NATURAL GAS PROCESSING

EMISSION REDUCTION ESTIMATOR

Develop a basis for the evaluation of your emissions reduction efforts in your sites. With some basic quantities, we can use our project experience to estimate the costs of the reduction implementation as well as the impact of lowering your Green House Gas (GHG) footprint.

We are the experts at getting natural gas to market. CANUSA EPC will complete a thorough natural gas processing analysis, draft a development plan and build business case that your board can approve. We have decades of experience dealing with low pressure solution gas to high pressure sour gas – across North America.

CANUSA EPC team brings clarity to the regulatory approval process. We have a full discipline team that will take your vision, ensure all required applications are completed, select the right technology vendors and execute the project from start to finish. With decades of project successes, we give you the confidence your project is designed with long-term operations in mind and always completed to your stakeholders’ satisfaction.

NATURAL GAS CHALLENGES WE OVERCOME

- Low pressure gas needs to be compressed to a higher pressure for transportation (compression)

- Removal of water from the gas (dehydration) to meet sales/pipeline specifications

- Selecting what natural gas liquids (NGLs) should be removed from the gas stream

- Natural Gas Liquids (NGLs) and handling of free liquids

- Natural gas refrigeration and separation

- Natural gas fractionation

- Splitting the natural gas into separate marketable products

- De-Methanizer

- De-Ethanizer

- De-Propanizer

- De-Butanizer

- Splitting the natural gas into separate marketable products

- Amine treating

- Removal of CO2 and or Hydrogen Sulfide (H2S) from the gas stream

NATURAL GAS PROCESSING SCOPE OF WORK

- Business case evaluation

- Regulatory and emission applications

- Natural Gas Liquids (NGLs) recovery evaluation and process modelling

- Amine treating process modelling

- Compression design and evaluation

- Process technology and vendor selection

- Project estimate, scheduling and controls

- Flare sizing and modelling

- Inlet and slugging capacity design and engineering

- Instrument air design

- Instrumentation and measurement design and engineering

- Gas conditioning

- Liquids storage design and engineering

- Sales meter design and vendor selection

- Electrical and control system design and engineering

- Piping design and stress analysis

- Structural design and engineering

- Civil and earth works design and engineering

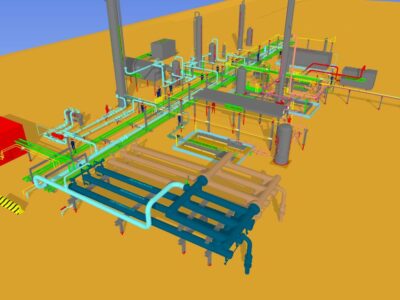

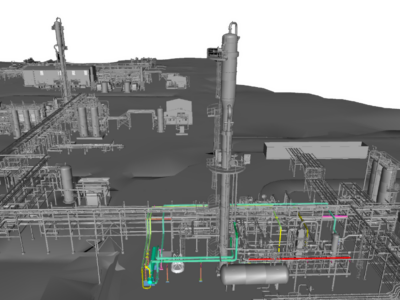

- 3D modelling and design

- Full service EPCM

- Procurement and construction management

200MMSCF/D SYSTEM EXPANSION

Grande Prairie, AB

15MMSCF/D Gas Processing

Canada

Gas Processing

USA

Compressor Station

USA

150MMSCF/D Gas Processing

Canada

Natural Gas Facility

Orloff, AB

Expandable Gas Treatment Facility

Carthage, TX

Cryogenic Plant Optimization

Vernal, UT

Cryogenic Electrical System

Douglas, WY

NGL Fractionation Train

Bantry, AB